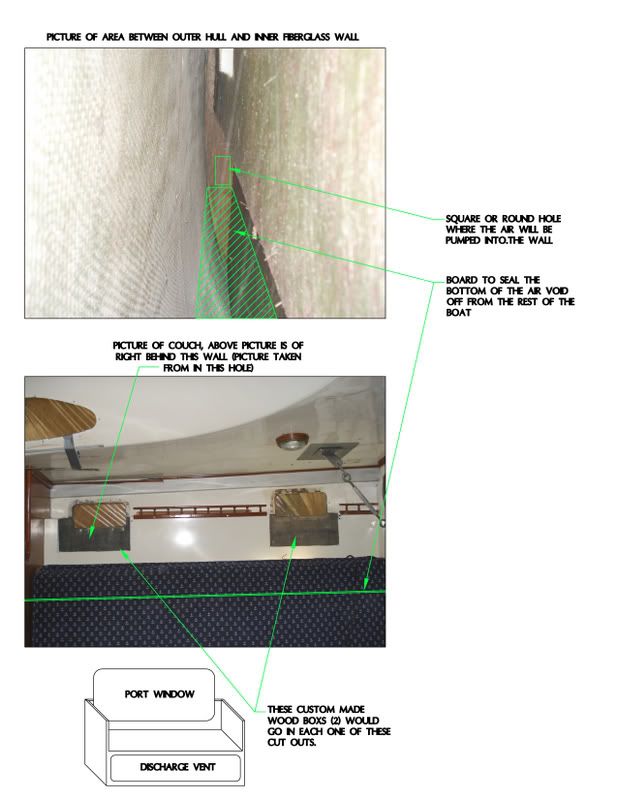

I my picture below you can see a hatch pattern the represents a board that I would like to install to make the air run in the wall cavity, and how the air will be let out of the space through some custom window boxes in the areas the previous owner made to install some port windows. The unit is gettting installed in a locker fwd (to the right in these pictures) of the couch, there is no problem running the duct work fwd into the v-berth.

Is this a bad plan, anyone see a better way to to this? I want to do it the best way possible.